Polidan® PEX

Polidan® PEX materials are silane moisture cure crosslinkable polyethylene grades mainly used for pipes&fittings.

PEX can also be used for other applications requiring high or low working temperatures, and improved chemical and/or abrasion resistance.

Key Features

● Improved resistance to oxidative aging

● Higher strength at elevated temperature

● Better chemical and chlorine resistance

● Higher heat resistance

● No-hydrolysis

● Improved low-temperature impact strength

● Superior resistance to crack propagation

● Better abrasion resistance

Performance

Polidan® PEX can be used where high or low working temperature, and improved chemical and abrasion resistance are required. All grades are ready-to-use on standard extrusion or injection molding lines.

Applications

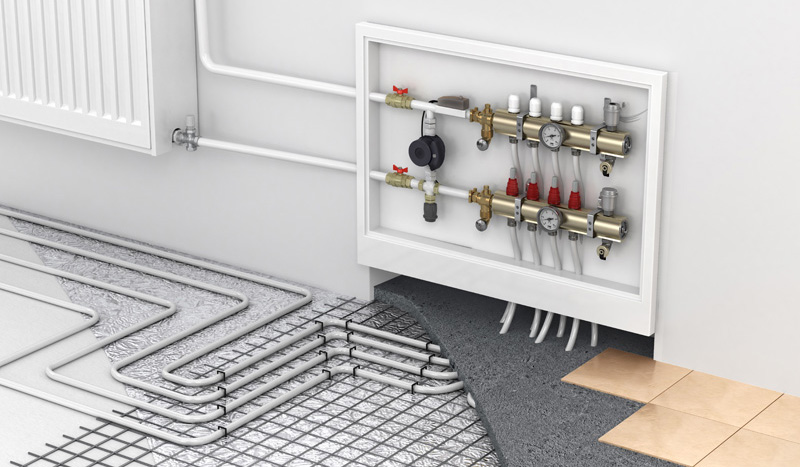

Building & Construction

Pipes and Plumbing components

Polidan® PEX is suitable for the production of pipes and fittings for Hot and Cold water plumbing system with improved pressure (up to MRS12.5) and chemical resistance compare to conventional materials. PEX is approved for indoor gas transportation according to the standard ISO 17484-1/2, thanks to the very low gas permeability and superior mechanical resistance.

Domestic appliance

Polidan PEX is used in hoses and molded parts for domestic appliance application, when high water-fluids temperature and chemical resistance is involved.

Polidan PEX flexible grades are also drinking water approved.

Flexible Hoses

Special Polidan PEX grades have been developed to substitute EPDM, polyolefins, silicone or PVC in pressure-braided flexible hoses or low pressure shower hoses thanks to the better micro-biological growth performance.

Oil & Gas

Lining, Umbilical and Composite Pressure Pipes

The Polidan® PEX System provides high temperature resistance in chemical environment, No-hydrolysis along with excellent long term strength, ESCR, notch and abrasion resistance.

Offshore & Onshore Distribution

Pipes produced using Polidan® PEX meet safely stringent requirements for Oil & Gas applications.

Automotive Fuel Systems

Optimal Pipes, Tubes and Hoses

Polidan® PEX is used for small diameter pipes for fluids transport inside the vehicle allowing wide operating temperature ( -40°C up to 125°C), high ESCR, RCP and abrasion resistance.

Industrial-Chemical Processing

Pipes & Fittings

Polidan® PEX system allows pipes and fittings to meet safely stringent requirements in applications like the conveyance of chemical products and Oil and Gas transportation. Polidan PEX is suitable for the production of big diameter pipes.

Alternative Energy

District, Geothermal and Solar heating

Polidan Pex can be used for hot water transport applications, allowing high pressure resistance together with long-term performances at high temperatures (up to 95°C), where traditional polyolefins are limited in performances.

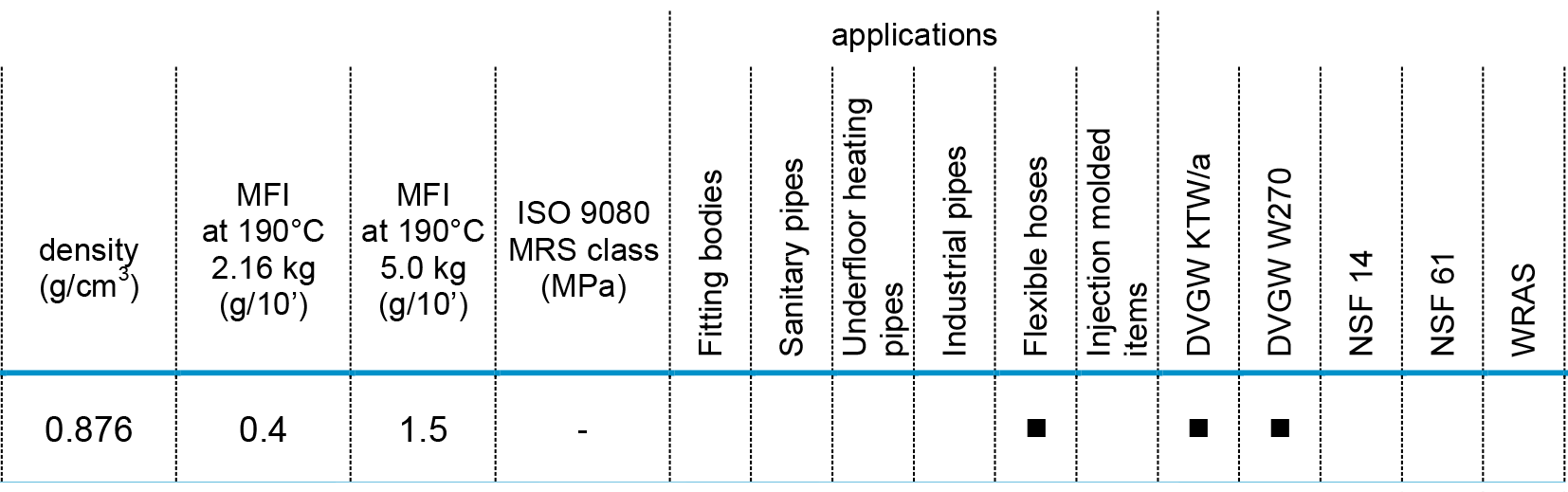

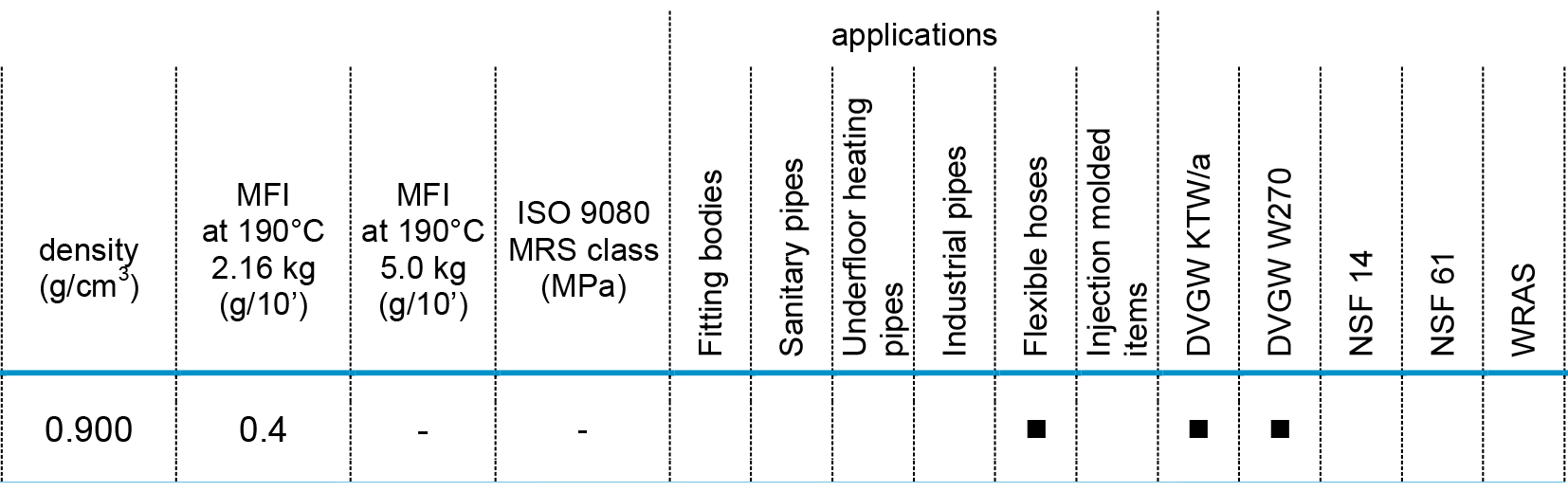

Ambient curing Silane crosslinkable PE with enhance flexibility. For extrusion or injection molding purpose of very flexible items or flexible/sealing parts that have to comply to stringent potable water contact requirements.

Ambient curing silane crosslinkable PE with high flexibility. It is used in flexible hoses, composite flexible pipes and multilayer fiber reinforced pipe design that have to comply to stringent potable water contact requirements.

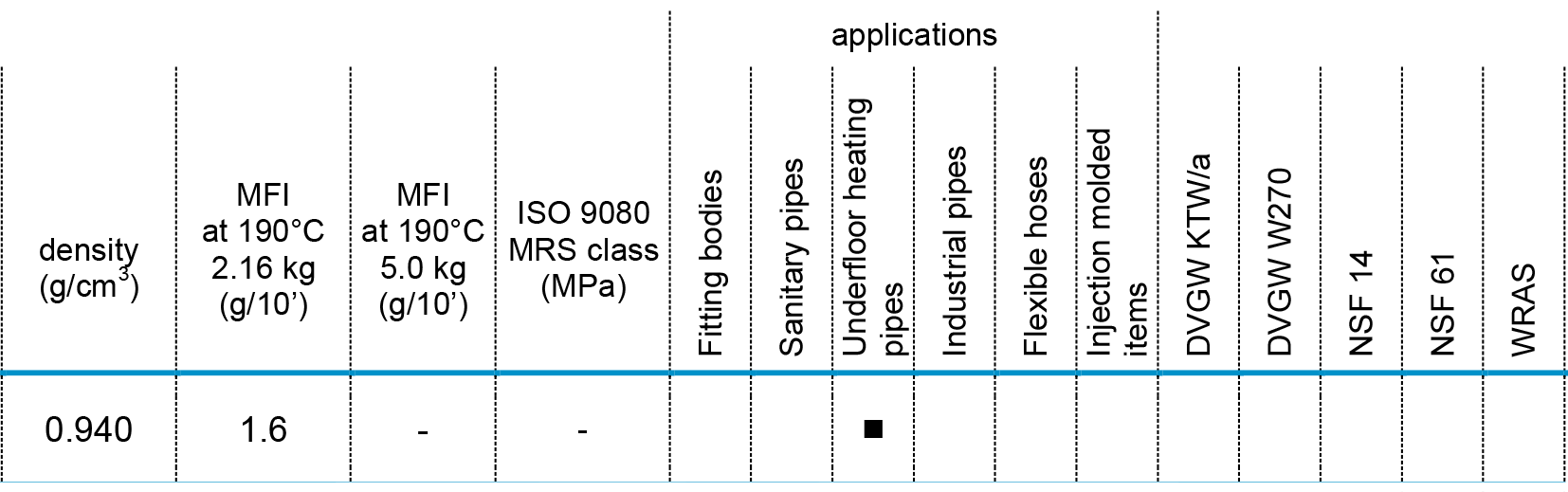

High-density, cross-linkable PE compound for flexible all-plastic pipes especially designed for underfloor heating system or flexible hoses with enhanced pressure resistance High-density.

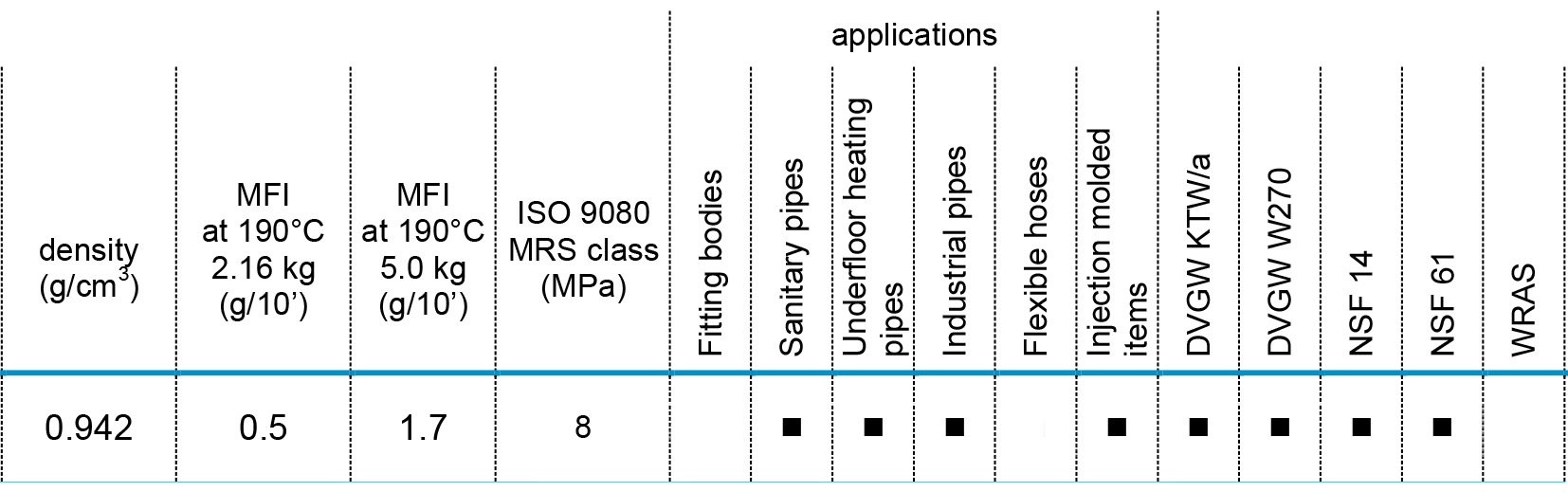

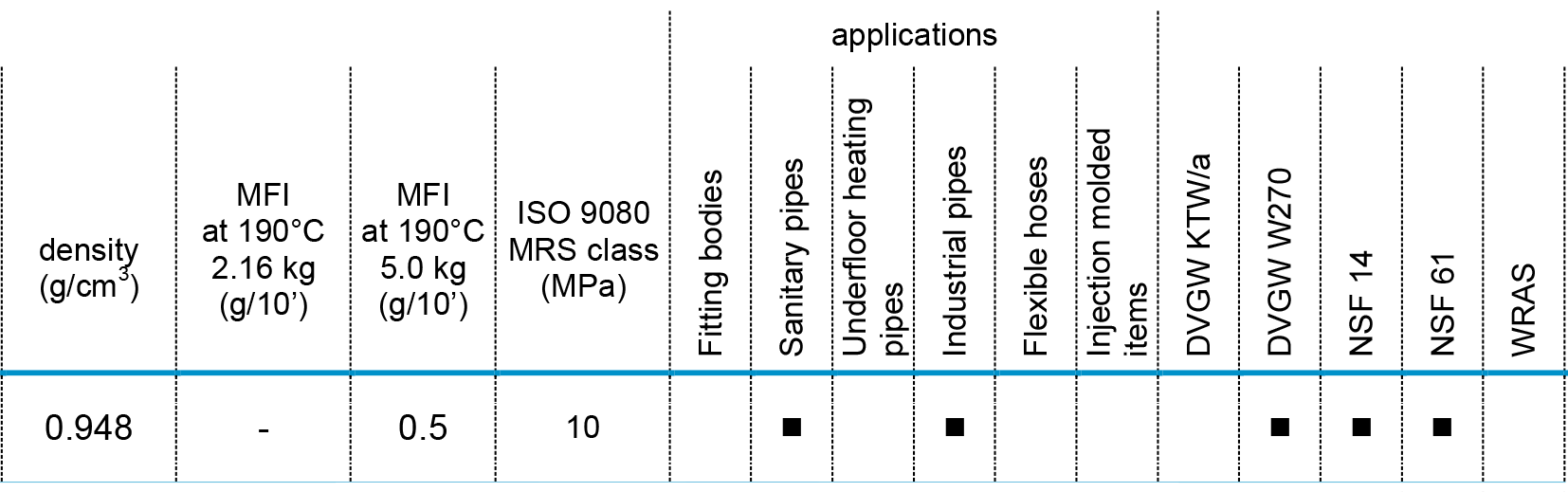

High-density, cross-linkable polyethylene compound for flexible and smooth-surface pipes in sanitary and heating environments.

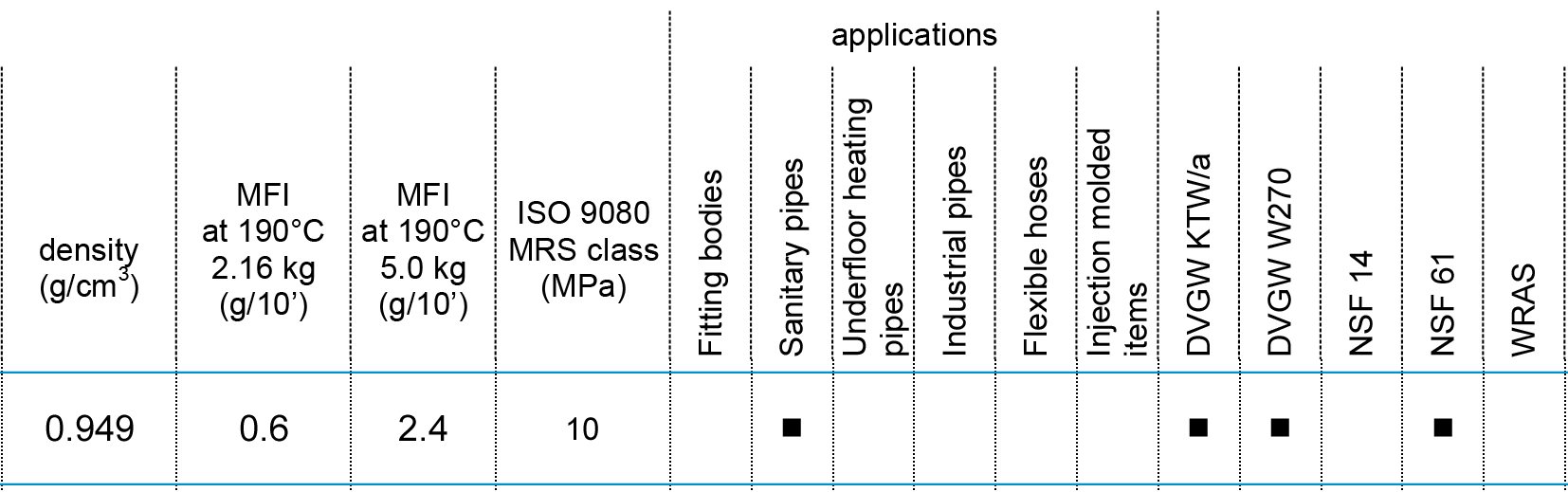

General purpose, high-density, cross-linkable polyethylene compound for all-plastic pipes.

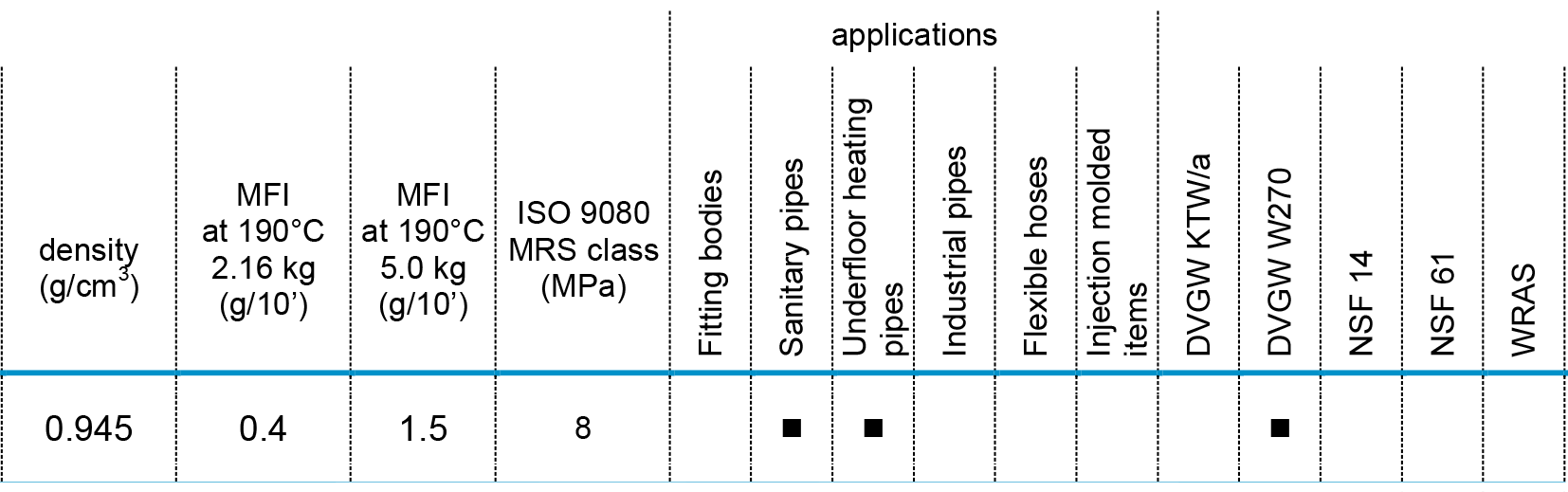

High-density, cross-linkable polyethylene compound for composite/multilayer sanitary and heating pipes, enabling high extrusion consistency even at low thicknesses.

Silane crosslinkable PE compound. It is used for flexible crosslinkable pipes enabling high extrusion consistency together with high coating properties in multilayer pipes.

Silane crosslinkable PE compound. It is used for monolayer or multilayer crosslinkable pipes with higher burst pressure resistance as well as enhanced thermal and mechanical properties.

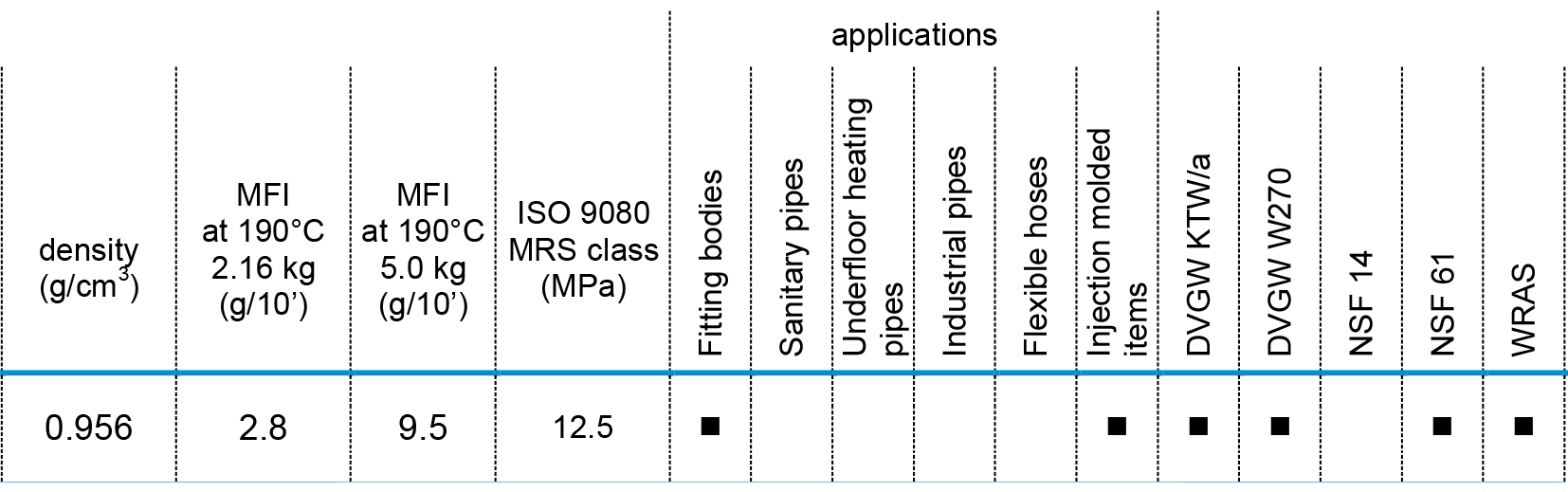

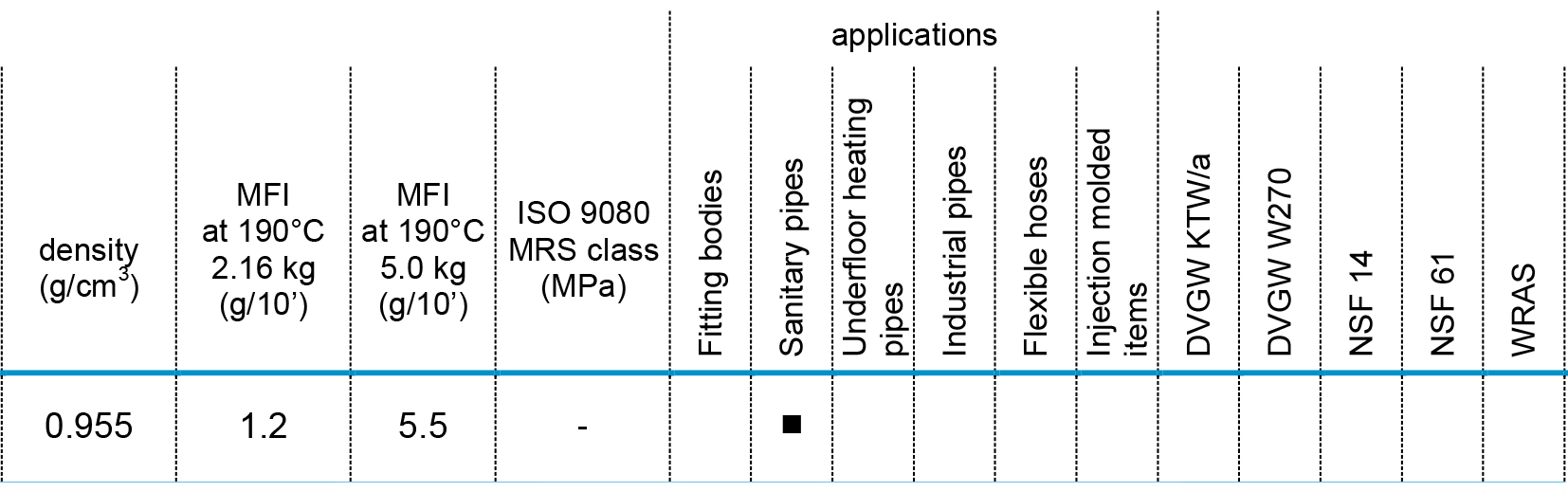

High-density, cross-linkable polyethylene compound for injection molding components that have high thermal, chemical and abrasion resistance.